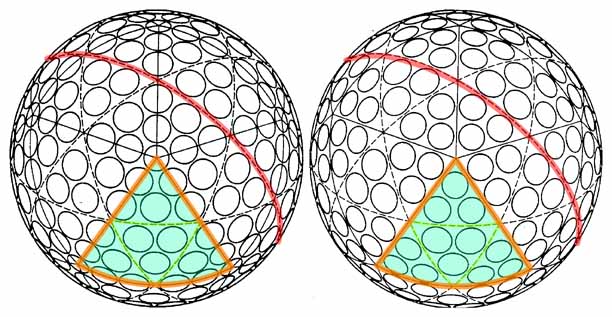

(These two balls are disclosed in US. Patent 4,560,168. As shown in the illustration, these two balls are easily made with a two-piece mold)

IMPROVE YOUR GOLF SKILL BY KNOWING YOUR RUBBER:

We have empirical evidence that that we play better sports once we understand the history, physics, kinetics, and chemistry behind the equipment and plays. Please read on, and you will find a way to shave your strokes. Based on our understanding of rubber material science and aerodynamics, we dispense invaluable golf lesson on this page.

HISTORY:

There were quite a bit of golf ball material innovations made in the past. There were golf ball patent applications for balls made out of steel and springs, compressed air, cork, wood, rubber, leather, feather, plastic, various dimple designs…

The earliest construction was a leather pouch filled with wet goose feather. It was called featherie. They took great care in making sure the ball was smooth by stitching the pouch inside out (before aerodynamic) This pouch was hardened, and painted white. Typical range was 150 yards.

The advancement came in 1845 with Gutta-Percha ball. It used smoke cured and molded core made from the Malaysian Sapodilla tree gum. It allowed the ball to have truer surface. Despite the truer, smoother surface, typical range was much less than featheries. Around this time, a professor at Saint Andrews University in Scotland discovered that smooth ball can fly farther if the surface was marked. Dimple was discovered.

The next advancement came from Mr. Coburn Hakell’s bounding billies patent in 1898. Haskell perfected a golf ball design using solid rubber core and tightly wound rubber band construction. By 1930, the golf ball with dimples was accepted as the standard design. This American design prevailed in the market place despite stiff opposition from the traditionalist on the other side of the pond. This ball gave the players what they wanted the most — distance.

MODERN POLYMER DESIGN:

As late as the year 2000, majority of the US. Open players were using rubber core and wound construction golf balls based on Haskell’s 1898 patent. It wasn’t until Tiger Woods used a solid-construction ball and won the Open by a record-setting fifteen strokes people took notice of modern polymer design. Today, it’s nearly impossible to find a wound ball in play. Solid construction usually consist of a two-, three-, or four-layer design, consisting of various synthetic rubber materials. By changing the blend of the synthetic rubber and layers you can have no-distance ball or ultra-far-illegal-distance balls. It is also possible to make a golf ball with self-correcting of hook or slice. Most designs are based on platonic solids such as icosahedron